Manufacturing Premium Rubber Components

At Parul Rubber Products (P) Ltd., manufacturing isn’t just a function — it’s a craft honed over decades

1

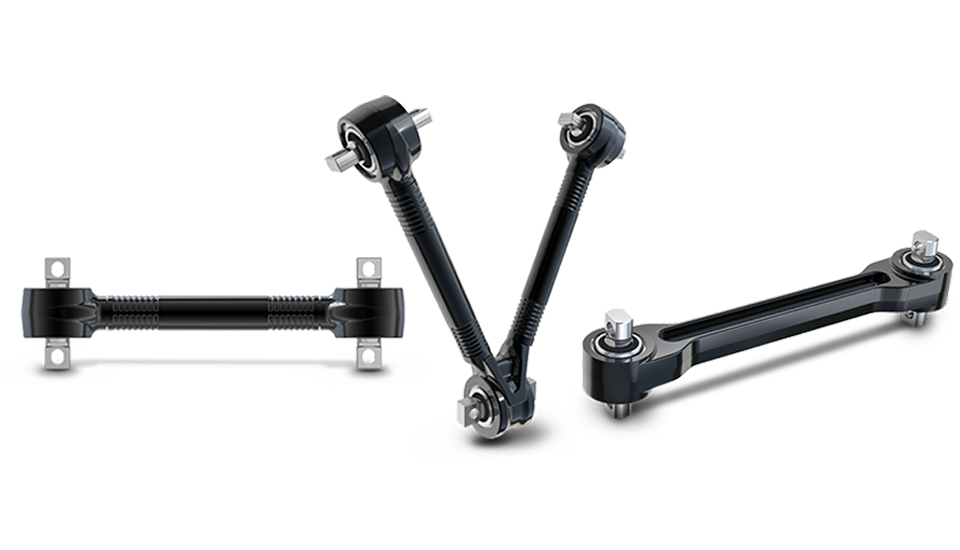

End-to-End In-House Capabilities

From rubber compounding and extrusion to sheet metal forming and assembly

2

State-of-the-Art Machinery

High-capacity extrusion lines, hydraulic presses, automated molding units, and dedicated testing laboratories

3

Quality at the Core

Our adherence to IATF 16949 and ISO 9001 ensures that each component lives up to international standards

4

Efficiency Meets Sustainability

We’re committed to sustainable manufacturing through efficient resource utilization

our products are the result of disciplined engineering, deep material expertise, and a commitment to delivering unmatched performance

Quality Management

Our Quality Management System (QMS) is designed to deliver excellence from raw material selection to final dispatch, ensuring that every component reflects our promise of performance, durability, and precision.

50+

Testing

Parameters

Our operations are aligned with globally recognized standards, reinforcing our commitment to zero-defect manufacturing, traceability, and process consistency

- Tensile Strength, Elongation & Hardness

- Dimensional Accuracy & Surface Finish

- Thermal Aging & Chemical Resistance

- Burst Pressure & Leak Testing

- Incoming Material Inspection

- Ozone Resistance Testing

- Dynamic & Fatigue Testing

- Material Traceability

- Compression Set & Recovery Analysis

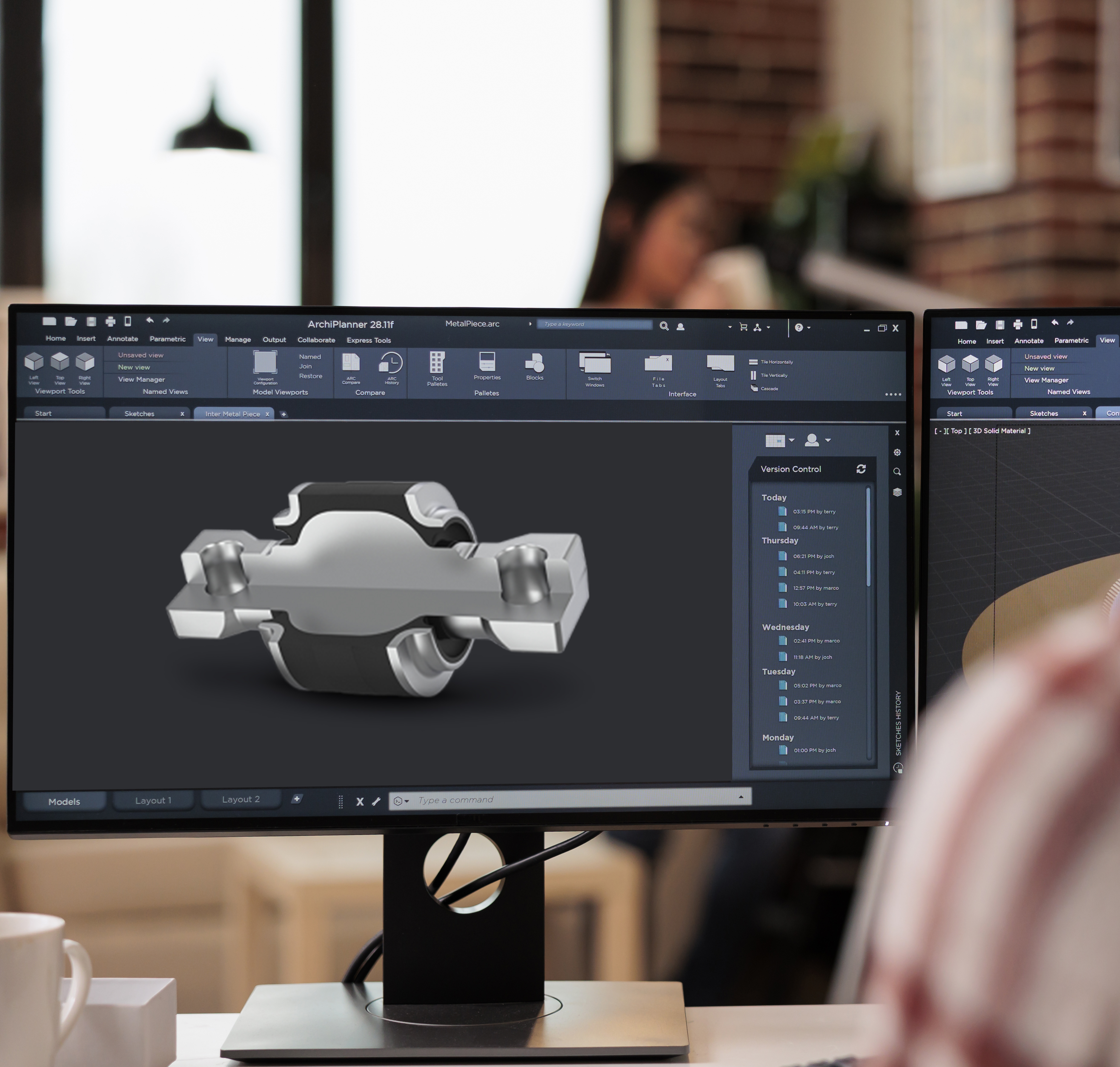

DESIGN &

ENGINEERING.

Our in-house Design & Engineering team is the powerhouse behind our innovative, application-specific solutions — seamlessly blending performance, reliability, and manufacturability.